UltraDoser 800S is the multi-purpose liquid nitrogen (LN2) dosing systemutilizing advanced cryogenic technologyand PLC programming. Chart engineers designed an ultra-efficient system for low to medium production line speeds to dispense a precise dose of LN2 into every container every time. The LN gasifies and is either trapped in the container to add rigidity or escapes with oxygen to inert the headspace.

UltraDoser™Technical Specifications

| Material | Stainless Steel Series 300* |

| Weight | 32lbs(14.5kg) |

| Body Dimensions | 18"H x 6"W(457.2x152mm) |

| Dosing Head Dimensitons | 9.5"H x 2"W(241x50.8mm) |

| Arm Reach | 12"to18"(304.8to457mm) |

| Head Pressure | 0.45 psi(0.03bar) |

| Nozzles | Ships with0.040",0.050",0.060" |

| System Utilities | LN2: 3 -22psi(0.2-1.5bar) |

| Steady State Consumption | 0.04gal(0.15公升)/小时 |

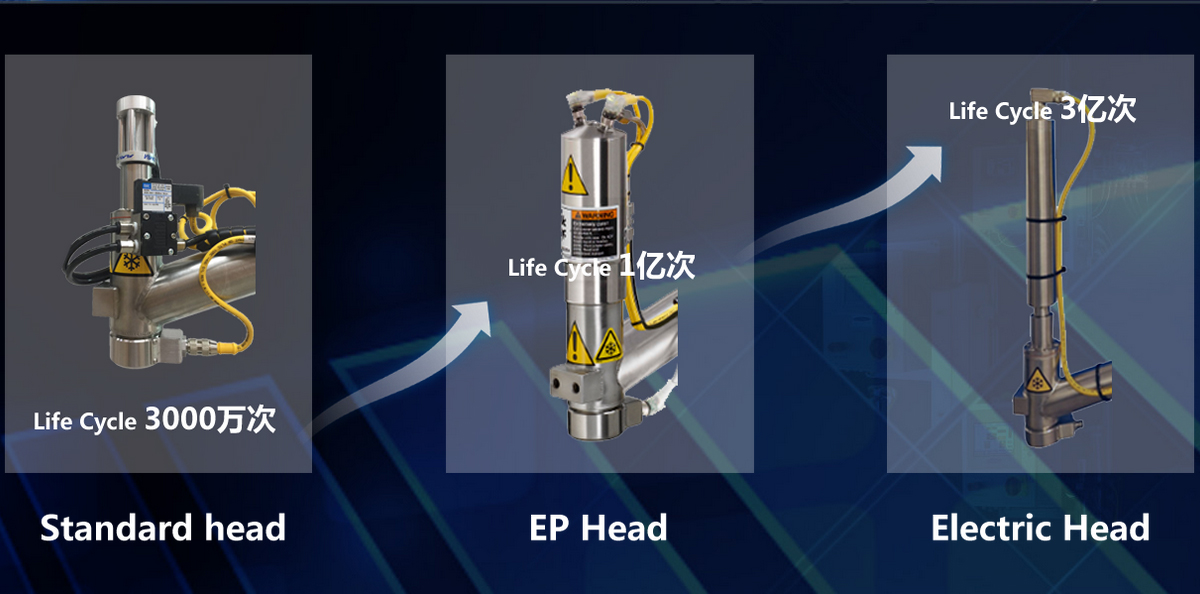

| EP Head Compatible | Yes |

| Quick Service Feature | No |

| Vacuum Insulated | Yes |

| Flexible Arm | No |

| SoftDose™ Compatible | Yes |

*304standard,316L available upon request | |

Controller Technical Specifications

| Model | 800S |

| PLC Platform | Siemens |

| Display | MonoKeypad |

| Dose Duration | 25 to1000 ms(1ms intervals) |

| Dose volume | 0.01 to4 grams/dose |

| Discrete Dosing (cpm) | 800* |

| Maximum Discrete Dosing (cpm) | 1000* |

| MicroDose™Technology | √ |

| Line Speed Auto Detect | √ |

| Electronic DoseTargeting | √ |

| Fixed Delay Mode | √ |

| Accuracy | ±5% |

| Multiple Language | |

| RemoteDose™ Capable | |

| Recipe Storage | |

| Certifications | CE,NEMA4X |

UltraDoser™ Dimensions

● Compact Size –enables installation in limited spaces

● Precise Dosing – delivers consistent, accurate dosing

● Discrete Dosing* – up to 2000 containers per minute

● Discrete or Continuous Dosing–change over defined by user

● SoftDose™ Compatible - proven technology for hot fill, powder,and granular applications

● RemoteDose™ Capable* - monitor and troubleshoot the system remotelythereby minimizing or eliminating system downtime**

● MicroDose™ Capable–designed specifically for tight pressure specifications

● IntelliDose™ Capable– automatic dose adjustments at any line speed between low/high points as defined by user

● Warranty –two (2) year warranty against manufacturing defects from time of shipment

* When paired with the 2K controller. Results achieved at Chart laboratory conditions.

** Access to the internal network is necessary for this function.

How it Works

LN2 is supplied to the UltraDoser by a vacuum insulated hose and flows into the dosing head. A sensor detects the speed of the line (encoder compatible); a second sensor detects the presence of a container. When a container is detected, the dosing head opens and dispenses an exactamountof pure LN2. A PLC (Programmable Logic Controller) is the brains behind integrating the sensors, controls and human interface.

Key Benefits

● Light weight PET – reduce the weight of PET

for cost and environmental saving

● Glass to PET Transition– eliminate glass

safety hazards and weight of containers

● Bottle Rigidity – maintain bottle shape even

with lighter weight containers

● Eliminate Paneling –increase the internal

pressure to off set paneling issues

● Oxygen Reduction – create an inert envir-

onment to preserve product freshness

● Extend Shelf Life –minimize oxygen levels

● Ease of Labeling – consistent bottle rigidity creates an efficient labeling process

● Reduce Nitrogen Consumption – measurable and repeatable liquid doses

● Maximize Warehouse Storage Space– increasing product stackability utilizes less square footage

● Stabilize Organic Products – extend shelf life without preservatives

玺奥国际贸易(上海)有限公司

Cryogas International Shanghai Co.,Ltd

Room 11, No. 55, Keelung Road, China (Shanghai) free trade zone

Tel:+86-21-61061937 61061939

Fax:+86-21-61061938

Tel:

021-61061937/61061939

Email:customerservice@cryogas.com.my